Fundamentals of Piping Inspection

Our Accreditations

Our Course on the “Fundamentals of Pressure Vessel Inspection Training” is both API (American Petroleum Institute) U approved as well as CPD (Continuing Professional Development) accredited.

Training and Inspection Services has gone through a rigorous due diligence check by both API & CPD to achieve such accreditations.

Our course trainers are some of the best in the energy industry who are scrutinized and accepted by API as U Trainers.

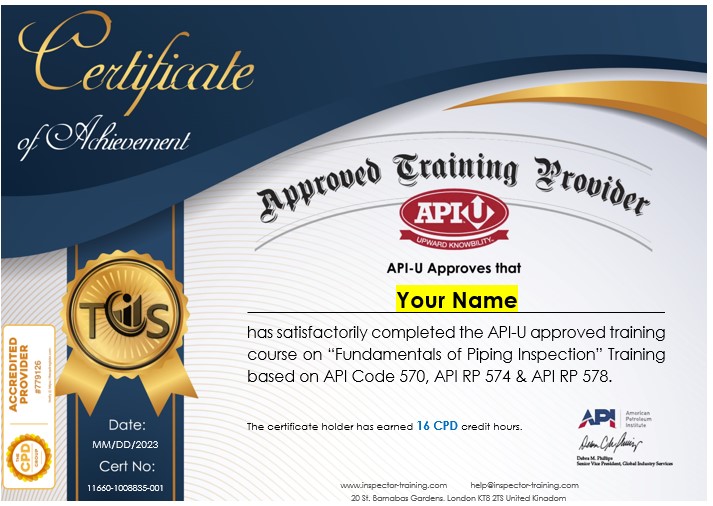

Below, please see our accreditation by API on “Fundamentals of Piping Inspection Training”.

All participants shall be awarded a certificate of completion by API U Approval and Logo that is also worth 16 CPD Credit Hours demonstrating satisfactory completion of the API U approved training course on “Fundamentals of Piping Inspection” based on API 570, API 574 & API 578.

You can mention the certificate of completion in your CV as proof of your achievement.

You can also submit the certificate of completion to any professional body of your choice as proof of your commitment to the mandatory Continuing Professional Development (CPD).

The certificate of completion is particularly useful if you are member of a professional body or institute, for example, if you are a chartered engineer, a professional engineer, an incorporated engineer, an engineering technician and wish to renew your certification or planning to apply for such certifications.

The certificate of completion can also be used when renewing your certifications as an API Authorized Inspector.

Course Outline

a) Course Memo

Quality like safety should be treated as a collective responsibility across any organization. Therefore, individuals working for energy industry specially those dealing with the design, fabrication, installation, commissioning, operation, maintenance and turnaround in oil and gas terminals, refineries, petrochemical plants and the like should know about the importance of compliance with codes, standards and recommended practices.

API codes, standards and recommended practices are not written with the intention of training individuals on general understanding, design skills, application, etc. nor API would respond to such queries.

This is exactly where we come into picture, that is, explaining the underlying concepts for codes and RPs requirements and recommendations, and how to apply them under various scenarios, reviewing case studies explaining what to follow and what to avoid.

Our courses would increase awareness, helps understanding the wealth of industry experience, knowledge, concepts and principles culminated within API Recommended Practices, codes & standards.

b) Course overview

The current course is specifically aimed at improving general understanding and knowledge of attendees on ‘’Fundamentals of Piping Inspection’’, enhancing their appreciation of inspection as well what to look for in terms of compliance with codes, standards and recommended practices.

The following recommended practice and code are discussed in sufficient detail from inspection and compliance perspective.

- API Standard 570, Piping Inspection Code

- API RP 574, Inspection Practices for Piping System Components

- API RP 578, Material Verification Program for New and Existing Alloy Piping Systems

Important topics are presented with flash cards & cue cards followed by Q & A sessions to ensure that attendees grasped the concept and application of codes and recommended practices.

Attendees shall have access to course material approximately 8 weeks prior to the classroom training via our website: https://inspector-training.com

Our course access is complemented with tutor support both before, during and after the classroom training.

Our team of course editors are chartered engineers, chartered quality professionals and API authorized Inspectors with significant experience in the fabrication, inspection, and turnaround activities in the onshore, offshore, green field & brown fields of the energy industry.

c) Course Calendar

This course is currently scheduled to be held as per the contract with Energy companies at their premises; at our facility, or by virtual training. The course can also be held for individuals subject to participation of minimum 6 persons.

d) Course Duration

This course is 2 days (16 Hours) long.

e) Maximum Number of Attendees

The maximum classroom size shall be 15 persons.

f) Who should attend

Managers, Engineers, Integrity Specialists, Operation & Maintenance personnel, Inspectors, QC Personnel, Coordinators and planners who work for energy companies, operating companies, gas terminals, oil terminals, EPC companies and Developers.

g) Assessment Method

There shall be no examination or scoring for the sake of having a relaxed yet high paced training environment, however, ample flash Cards and cue cards shall be presented.

Sample questions are also presented and discussed in the class plus Q & A sessions are held to clear any ambiguity ensuring that participants have grasped the concepts behind dos and don’ts and how to implement them.

h) Certificate of Completion

Participant shall be awarded Certificate of Completion as an API U approved training course that is also worth 16 CPD Credit Hours.

i) List of Modules

Module 1 – API RP 574

In this module, we shall discuss API RP 574 – Inspection Practices for Piping System Components; explaining important concepts.

Module 2 – API 570

In this module, you shall learn about: API 570 Piping Inspection Code: In-service Inspection, Rating, Repair, and Alteration of Piping Systems.

Module 3 – API RP 578

In this module, you shall learn about: Material Verification Program or Positive Material Identification (PMI) for New and Existing Alloy Piping Systems

Module 4 – Flash cards

In this module, we shall summarize important terms and concepts of what we learned so far highlighting important topics plus basics of NDE, WPS & damage mechanism.

j) Course Itinerary

Day 1(AM): Introduction, API RP 574 Piping Inspection Practice.

Day 1 (PM): Review of API 570 Piping Inspection Code.

Day 2 (AM): API 570 Piping Inspection Code (continued); Review of API RP 578 (PMI).

Day 2 (PM): Review of Important topics in piping vessel inspection presenting flash cards, cue cards; and Q & A sessions.

k) Our Continuous improvement Program

Standards and recommended practices are normally revised every two years and applicable 6 months after publication. We review the course material on annual basis to ensure:

- Revisions in RPs, codes and standards are addressed

- Attendees and trainers comments and feed back is addressed

- Assess the course content to verify that it is easy to understand, reflects the scope and whether any further improvement could be made in terms of content and presentations.

All our revised course materials are then submitted to API for review and re-approval.

At the end of each course, we request attendees to score us on:

- Instructor’s Personal Knowledge

- Instructor’s Performance

- Course evaluation

- Training Center facilities

- Overall program assessment

All assessments are reviewed by us as well as sent to API.

Please help us improve with your comments and suggestions. We are also interested to know about any other topics that you may be interested in or any bespoke courses that your company needs us to develop.

You can always call or text us via WhatsApp or email us. We normally respond within minutes during working hours.

For any queries, please write to us:

help@inspector-training.com

or just text or call us on WhatsApp.

[/vc_column_text][/vc_column][/vc_row]We are in knowledge sharing business

[/vc_column_text][/vc_column][/vc_row]Course Features

- Lectures 19

- Quizzes 0

- Duration 16 hours

- Skill level All levels

- Language English

- Students 0

- Certificate Yes

- Assessments Yes