In this module, you shall learn about:

Pipeline Inspector should be monitoring and reporting all aspects of pipeline construction;

So, the inspector is practically representing the owner in the field.

API RP 1169 defines the inspector as somebody who is qualified to:

As you can see, the job description covers a long list of topics:

to name a few without the need to have specialization in any of them whatsoever, but just a general knowledge.

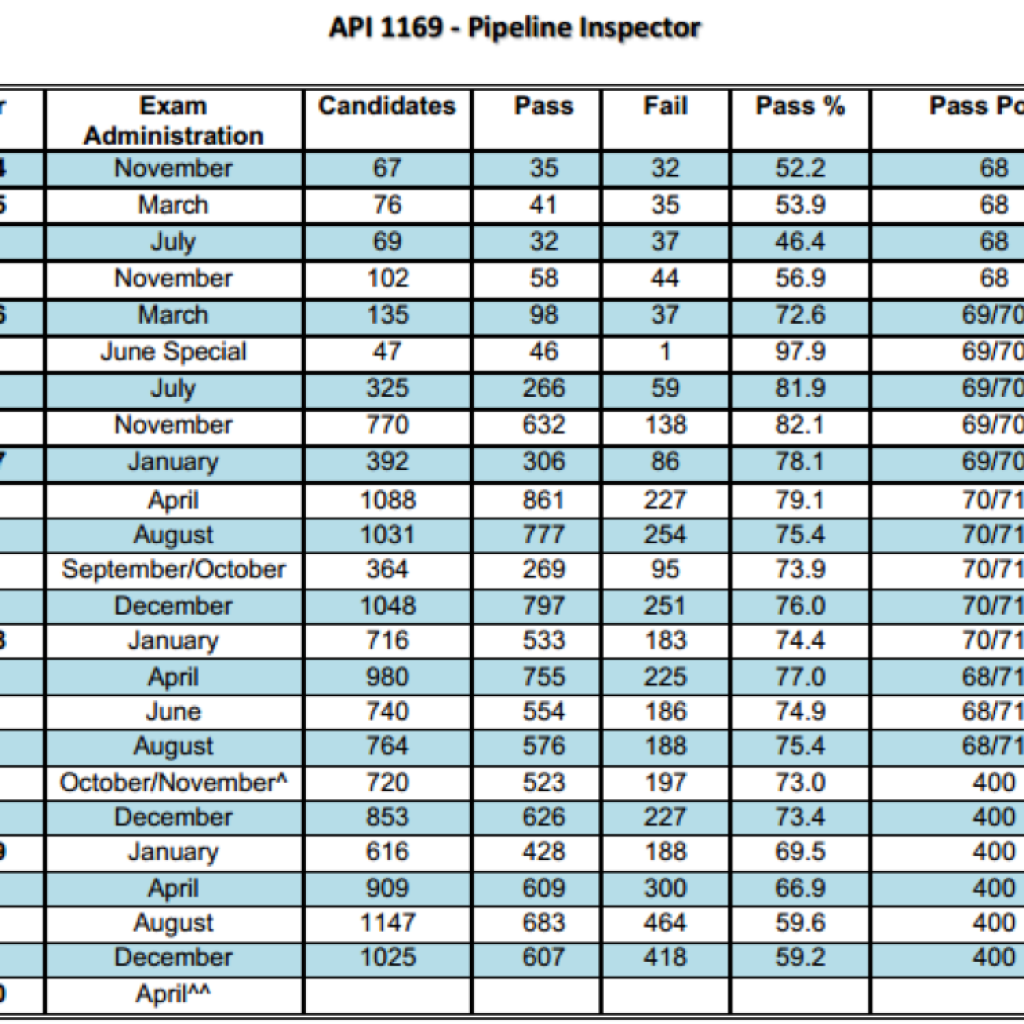

API 1169 is the fastest growing certification among all the other dozen certifications and has a good passing rate (60%) so far; although the pass rate has been declining over the past 8 years.

API 1169 exam has some peculiarity over other API exams, namely:

b) API RP 1169 basically explains what is expected from the inspector but does not explain how? On the other hand, the practical guide has extensive checklist showing what need to be verified or ticked by the inspector.

These areas are categorized by construction phase as well as by topic.

f) Although ASME B31.4 (Pipeline Transportation Systems for Liquids) and ASME B31.8 (Gas Transmission and Distribution Piping Systems) has been brought as part of body of knowledge, but API has noted within the BoK that these ASME Documents are recommended for general knowledge only and are not required for the exam; because all exam related information contained within ASME B 31.4 & B31.8 documents can also be found in API RP 1169 and CEPA/INGAA’s Practical Guide for Pipeline Construction Inspectors.

Nevertheless, we have dedicated course module 12 to these ASME codes so you may understand where those information brought within API RP 1169 and INGAA are coming from.

g) During the exam, you shall have access to both US and Canadian sets of HSE documents (12 US and 9 Canadian).

We have highlighted important information and included them in the course. The search button is disabled but the content lists are available. You should have a fair idea where you can find the answer to open book questions.

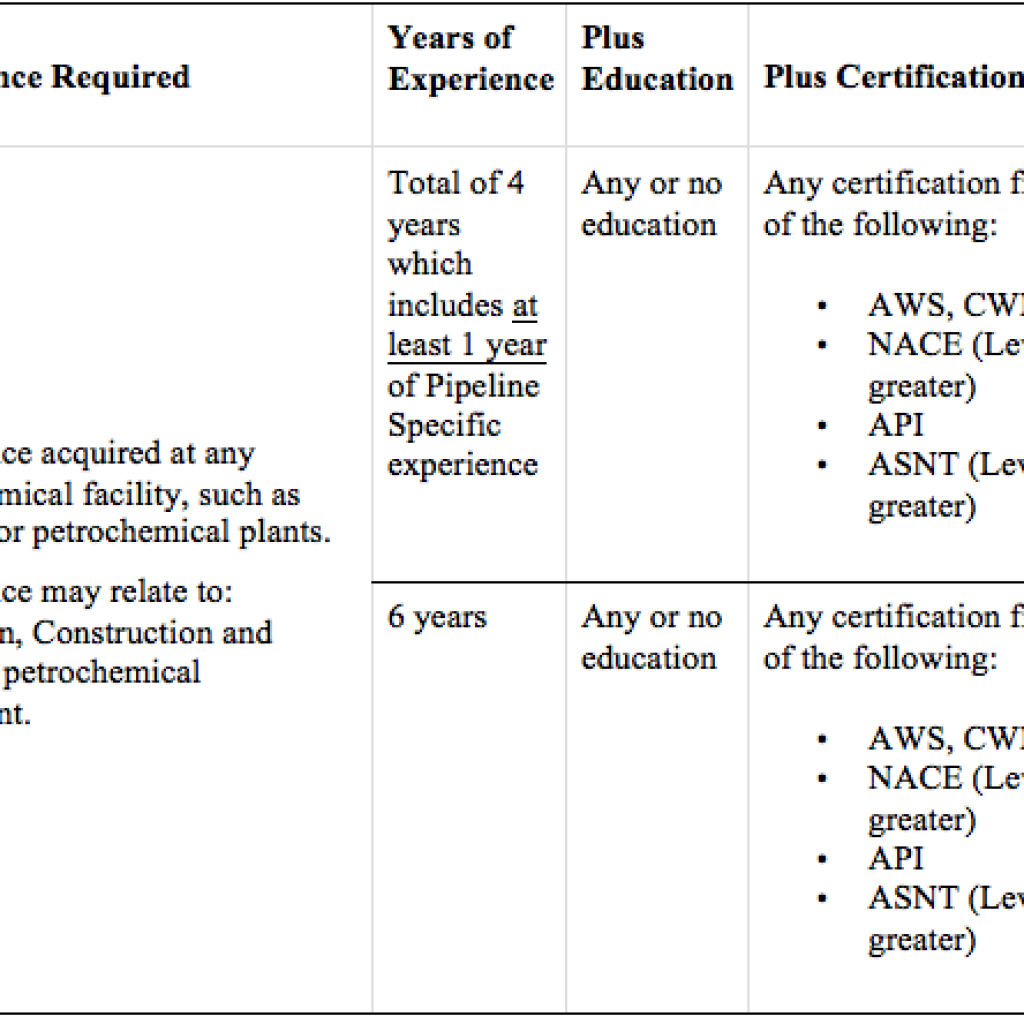

You should have at least 3 years pipeline inspection experience or 4 years pipeline non inspection experience (1 years experience is reduced if you have BS or 2-year degree in a technical discipline).

Below please find the prequalification requirements. Contact us if you are in doubt.

Most of questions are common sense if you are familiar with the various phases of pipeline construction.

We have provided lots of pictures to give you the feel factor.

We have explained the quality terms in an easy to understand format and also highlighted the potential exam questions (in yellow).

API BoK specifies the following topics for exam questions:

− Alignment sheets (e.g., extra workspace, PI locations, special conditions)

− Specifications (e.g., width, right of way, grubbing, topsoil segregation)

− Permits (e.g., road crossing, road access, railroad, encroachment)

− Special landowner requirements (e.g., line list)

− Written and/or electronic reporting

− Materials identification (e.g., pipe grade, wall thickness, coating, heat and pipe number)

− Materials defects / condition

− Handling requirements (e.g., lifting, loading and unloading, equipment, stacking, securing)

− Pipe tally / pipe placement (e.g., placed per alignment drawings, seam locations)

− Specifications (e.g., minimum equipment requirements)

− Written electronic reporting (e.g., stringing distances and skips, number of joints)

− Pipe ovality and wrinkles (e.g., CFR192)

− Proper bending equipment (e.g., liners, mandrels, shoes, angle measurement)

− Specifications (e.g., bending requirements, tangents, maximum angles, seam alignments, coating or metal damage)

− Written electronic reporting (e.g., bend location, as built)

− Specifications, qualified procedures, qualified personnel, documentation, material/consumable control, testing (equipment and products)

[/vc_column_text]

− Specifications, clearances, type of bores, voids, crossing agreements/permits, cased vs. uncased crossings, pipe condition

− Specifications, qualified procedures, qualified personnel, documentation, material/consumable control, testing (equipment and products)

− Proper equipment (e.g., lifting, cradles, slings)

− Specifications (e.g., spacing, location in ditch, depth, ditch preparation, sandbag placement, benching

− Lifting plans (e.g., boom spacing, lift height, boom size, number of booms)

− Written / electronic Reporting (e.g., amount, damage, holiday detection)

− Specifications (e.g., alignment, OQ)

− Written / electronic reporting (e.g., location, amount)

− Material identification (e.g., pipe number, heat number, cut off length)

− Material Placement (e.g., transition, pipe support)

− Alignment sheets (e.g., location, type, length)

− Specifications (e.g., connection, wire size, anode ground beds, size, length, location)

− Written / electronic reporting (e.g., location, amount, as-builts, type)

− Redline drawings, alignment sheets showing final as built conditions, dimensions, and characteristics of the pipeline (e.g., weld maps/logs, NDE maps/logs, PI/POT locations, depth of cover, test leads, material and coating information).

− Proper equipment (e.g., type, padding requirements, rock shield, erosion control, weights)

− Padding pipe (e.g., depth, material size, compaction, foam)

− Specifications (e.g., padding amount, material size, bench spacing, compaction, crown)

− Written / electronic reporting (e.g., quantity and location)

− Buoyancy control (e.g., types, installation, spacing, documentation)

−Alignment sheets (e.g., special conditions, mile marker placement, re-vegetation, bank stabilization)

−Landowner requirements (e.g., damages, special conditions, fences, restoration)

−Equipment (e.g., LGP, decompaction, seeding)

−Horizontal drilling process, drilling fluids, drill path/profile, geotechnical studies, pull force, radius of curvature, entry/exit points, entry/exit angles)

−Testing, gauge plate inspections, deformation

Not a member yet? Register now

Are you a member? Login now