Pre-qualification and area of examination

No prequalification (education, experience) is required.

The API SIRE – Source Inspector Rotating Equipment certification is open to applicants with any experience in the petroleum and petrochemical industries, as well as applicants wishing to gain industry experience.

The exam is 3.25 hours long and there are 110 questions, of which only 100 are scored.

The remaining 10 are pretest, which are not scored. Scored and non scored questions are shuffled and unmarked, so, you need to answer all questions.

All questions are multiple-choice and closed-book. Paper and reference materials are not allowed into the examinations.

Although exam scores are scaled in order to standardize the level of difficulty, you are required to answer roughly 70 scored questions correctly (minimum 400 on a scale of maximum 500).

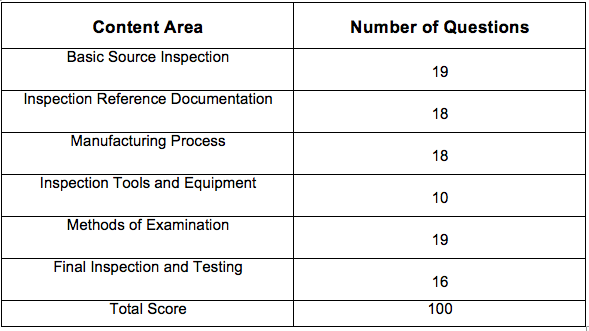

API SIRE covers a wide range of inspection activities, codes, recommended practices and standards.

You are scored for your performance in the following areas during the examination.

Reference Study Materials

The following standards and recommended practices need to be studied for API SIFE examination:

API RP 578, Material Verification Program for New and Existing Alloy Piping Systems; 3rd Edition, February 2018

API Standard 610, Centrifugal Pumps for Petroleum, Petrochemical and Natural Gas Industries; 11th edition, September 2010

API Standard 611, General-Purpose Steam Turbines for Petroleum, Chemical, and Gas Industry Services; 5th edition, September 2008, reaffirmed February 2014

API Standard 614, Lubrication, Shaft-Sealing and Control-Oil Systems and Auxiliaries for Petroleum, Chemical and Gas Industry Services; 5th edition, April 2008

API Standard 617, Axial and Centrifugal Compressors and Expander-compressors for Petroleum, Chemical and Gas Industry Services, 8th edition, August 2016

API Standard 618, Reciprocating Compressors for Petroleum, Chemical, and Gas Industry Services, 5th Edition, December 2007, reaffirmed August 2016

API Standard 619, Rotary Type Positive Displacement Compressors for Petroleum, Petrochemical and Natural Gas Industries; 5th Edition, December 2010

API Standard 677, General-Purpose Gear Units for Petroleum, Chemical and Gas Industry Service; 3rd edition, April 2006, reaffirmed November 2016

API Standard 692, Dry Gas Sealing Systems for Axial, Centrifugal, and Rotary Screw Compressors and Expanders; 1st edition, June 2018

ANSI HI 14.6, Rotodynamic Pumps for Hydraulic Performance Acceptance Tests, 2016

ASNT SNT-TC-1 A Personnel Qualification and Certification in Non destructive Testing 2011 EDITION

ASME Section II Materials, Part A, B, C, D

ASME Section V Non destructive Examination: Definitions in Subsection A, Article 1, Appendix I and Subsection B, Article 30, SE-1316 • Articles 1, 2, 4, 5, 6, 7, 9, 10, 23 (section 797 only)

ASME Section VIII Rules for Construction of Pressure Vessels, Division 1; Acceptance Criteria • USC 56-57 • Appendix 7- Examination of Steel Casting

ASME Section IX Welding and Brazing Qualifications, Welding only: QW 100-190; QW 200-290; QW 300-380; QW 400-490; QW500-540

ASTM A703 Standard Specifications for Steel Castings, General Requirements, for Pressure Containing Parts, 2018

MSS-SP-55 Quality Standard for Steel Castings for Valves, Flanges, Fittings and Other Piping Components, 2011

SSPC – PA 2 Procedure for Determining Conformance to Dry Coating Thickness Requirements, January 2015

SSPC‐SP1 Solvent Cleaning, 2015 SSPC‐SP3 Power Tool Cleaning, 2004

SSPC‐SP5 NACE 1 White Metal Blast Cleaning, 2007

SSPC‐SP6 NACE 3 Commercial Blast Cleaning, 2007

SSPC‐SP7 NACE 4 Brush-Off Blast Cleaning, 2007

SSPC‐SP10 NACE 2 Near-White Blast Cleaning, 2007

SSPC‐SP11 Power Tool Cleaning to Bare Metal, 2013

As you can see, it touches a wide range of subjects that a rotating equipment inspector shall be familiar with; although not as an expert with an in-depth knowledge.

API provides a very useful guide for SIRE that covers all the possible activities for inspection management of rotating equipment packages.

You can download the ‘’Study Guide for Source Inspection and Quality Surveillance of Rotating Equipment’’ for free from below link:

Study Guide for the Source Inspection of Rotating Equipment

Our E- Leaning Modules

The following modules are presented during our e-learning course to cover the body of knowledge or reference study materials.

Module 1: Exam & study tips

Module 2: API SIRE Scoring, Reference Documents & Exam Tips

Module 3: Guide for Source Inspection & Quality Surveillance of Rotating Equipment

Module 4: SSPC & MSS & ASTM A703 & A182

Module 5: ASME Sec. II; Materials; Parts A, B, C, D

Module 6: ASME Sec. V; Non destructive Examination

Module 7: ASNT SNT TC‐1A; NDT Personnel Certification

Module 8: ASME Sec. IX; Welding and Brazing Qualifications

Module 9: ASME Sec. VIII-Construction code for Pressure Vessels- Div. 1 & 2

Module 10: API 578; Material Verification Program (PMI)

Module 11: API Standard 610; Centrifugal Pumps

Module 12: API Standard 611; General Purpose Steam Turbine

Module 13: API Standard 614, Lubrication, Shaft-sealing

Module 14: API Standard 617, Axial and Centrifugal Compressors

Module 15: API Standard 618, Reciprocating Compressors

Module 16: API Standard 619, Rotary Type Positive-Displacement Compressors

Module 17: Module 18- API SIRE – API Standard 677, General-Purpose Gear Units

Module 18: API Standard 692, Dry Gas Sealing Systems

Module 19: HI 14.6, Rotodynamic Pumps Module

Module 20: Publication Effectivity Sheet Highlights

Module 21: API SIRE – Flash Cards – potential exam questions

Module 22: 3 sets of mock exams plus four sets of practice questions.

Our API SIFE course (E-learning as well as the blended or hybrid (e-learning + classroom training) including our mock exam questions are specifically aimed at covering the reference materials.