Welding current is like volume of water while voltage is like the water pressure just like When you are watering a plant with a hose.

That is why; when you increase the voltage, it means you are having a higher pressure in the water hose.

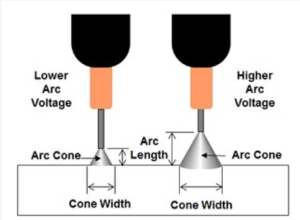

Higher voltage (higher pressure in the water hose) not only allows welder to weld from a further distance (just like when you can water the plant from a further distance(; but also increase the weld width (you are able to water a wider area).

Current is the deposition rate (volume of water). If the welder controls the distance and you want a uniform and constant weld deposition rate, then, you set the current as constant but; here the voltage is variable. This is to compensate for changes in distance.

For example, in Tungsten Inert Gas (TIG) welding; where the welder changes the distance (from tip of electrode to the base metal), the power supply is always a constant current to have a uniform depositionrate but the voltage is variable in order to compensate for changes in distance.