Inspector Duties:

The manufacturer/fabricator is responsible for the quality of all their Manufactured and & Fabricated products, which includes not only goods workmanship, but also compliance with all codes, standards and specifications contained in the contractual agreements. This is regardless of whether the manufacturer has made the components and equipment himself or subcontracted it.

The inspector is responsible for performing the quality surveillance activities at the Supplier/Vendor facilities in accordance with the applicable ITP.

The inspector should ensure that:

- Manufacturer & Fabricator has a documented method describing how to perform the work.

- Supplier/vendor personnel have proof of training and qualifications

- Supplier/vendor personnel performing the work have immediate access to the relevant procedures. For example, welders have access to the WPS or welding instruction. NDE personnel have access to the approved NDE procedures.

- The acceptance criteria comply with the project specification or the applicable codes and standards.

- The results are documented

- Rework and repair is approved by the purchaser and verified by the Inspector.

Continuous Improvement:

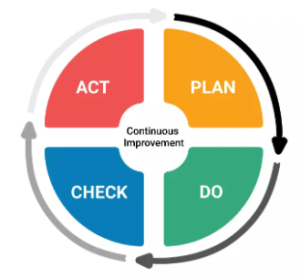

At the completion of the inspection activities; a PDCA cycle (plan, do, check, act) review is taken as part of a continuous improvement program to determine which activities went well and where improvements/adjustments could/should be made. Any such system improvements should be documented and presented to the inspection or quality manager and coordinators for implementation.

Inspector Continuous Improvement

There is also a personal improvement level. Inspector could self check by asking himself the following questions:

- Are there some industry codes and standards that I should be more familiar with?

- Are there any safety and/or personal conduct improvements I can make?

- Can I improve the way I write the various inspection reports?

- Do I be better prepared (for example, need to improve my review of project documents) before showing up at the SUPPLIER/VENDOR site?

- Can I improve the way I conducted the pre-fabrication meeting (prepare a tailor made agenda/checklist and turn it around for feedback prior to the meeting)?

- Can I improve the timeliness of closing out my part of the inspection activities (have a schedule revised periodically, focusing on delayed activities)?