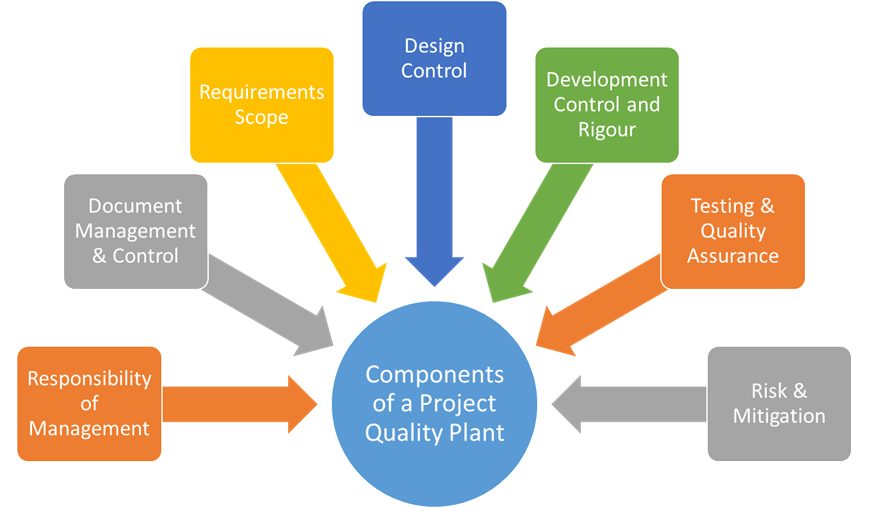

Project Quality Plan (PQP) is normally required for criticality “1” packages. It is based on ISO 10005 Quality management — Guidelines for quality plans. It would have the same requirements as ISO 9001 QMS but intended for implementation at project level.

A Project Quality Plan typically includes:

∙ Key Personnel and their responsibilities

∙ Contract review to ensure supplier has sufficient resources in terms of manpower, know how, infrastructure to do the job

∙ Design control (input, output, verification, validation)

∙ Document and data control (revision & numbering for traceability while archiving outdated documents)

∙ Purchasing (subcontractor for services and raw material, ensure controls in place)

∙ Control of customer-supplied product (free issued material supplied by the purchaser/client if any, traceability, proper storage, quarantine non conforming product and ask the client for disposition)

∙ Product identification and traceability (including raw material traceability and marking)

∙ Process control (QC procedures such as NDE examination procedure, test procedures, WPS, function test procedure, pressure test procedure)

∙ Inspection and testing (reflected within package Inspection and Test Plan)

∙ Control of inspection, measuring and test equipment(Calibration program includes calibration procedures, register, test reports & certificates)

∙ Inspection and test status (Test reports, mill test report, test records)

∙ Control of nonconforming product (NCR Procedure, register and reports)

∙ Corrective and preventive action (normally addressed within NCR reports)

∙ Handling, storage, packaging, preservation and delivery (addressed within packing and shipping procedure, lifting plan for heavy components or equipment normally over 2000 kg. (if needed) )

∙ Control of quality records (reflected within MRB/MDB or manufacturer record book and it’s index)

∙ Auditing (Audit procedure, audit schedule, audit findings and follow up)

∙ Training (supplier to demonstrate how he ensures his personnel and subcontractors have the required qualification, training and competency, evidence would be the training matrix, qualification record, experience record).